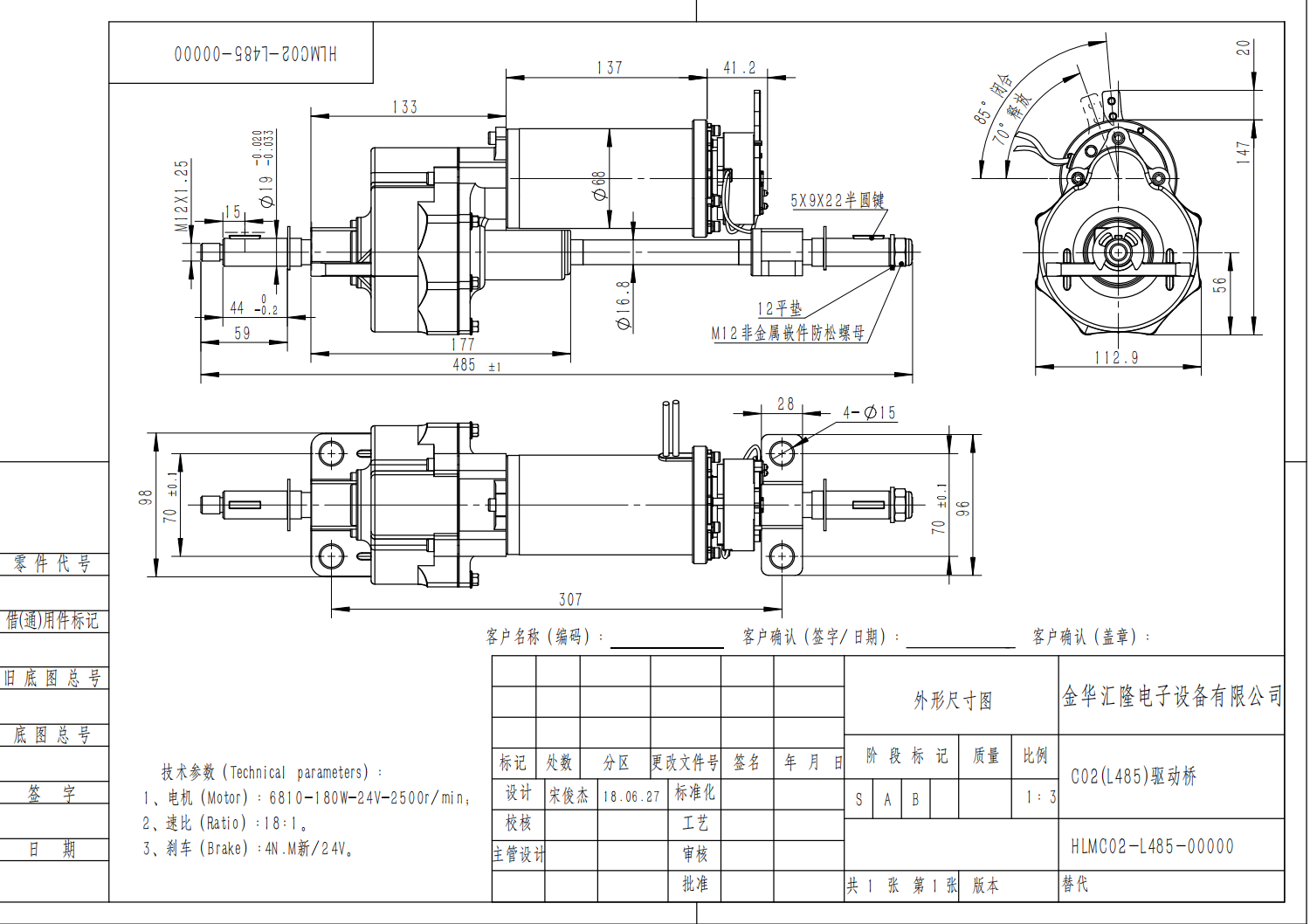

C02-6810-180W Electric Transaxle

Core Applications

The C02-6810-180W Electric Transaxle is designed for a variety of applications where reliability, efficiency, and precision are key:

Material Handling: In warehouses and distribution centers, this transaxle can power conveyor systems and forklifts, ensuring smooth and efficient movement of goods.

Construction Equipment: On construction sites, it can be used in compact machinery like mini excavators and telehandlers, providing the necessary torque for digging and lifting.

Automated Guided Vehicles (AGVs): In manufacturing and logistics, AGVs rely on precise and reliable transaxles to navigate complex environments and transport materials.

Medical Equipment: In healthcare settings, this transaxle can be used in equipment that requires precise movement and control, such as patient lifts and diagnostic machines.

How does the transaxle improve efficiency in agricultural machinery?

The application of electric transaxle in agricultural machinery can significantly improve efficiency, here are some specific examples and benefits:

Improved energy efficiency and performance: Based on a European Commission research project, the new third-generation electric transaxle is designed to provide flexibility to adapt to different torque and speed requirements and has a compact design to meet the needs of the agricultural field. This high-efficiency transmission system can enhance vehicle autonomy, increase load capacity and battery life, thereby reducing farmers’ operating costs by up to 50%.

Improved soil structure and permeability: Controlled Traffic Farming System (CTF) can reduce the energy required for field transportation by reducing soil compaction. Improved soil structure and rainwater infiltration can reduce runoff and erosion, thereby reducing the flow of nutrients and sediments into waterways.

Reduced NOx emissions and improved nitrogen use efficiency: CTF reduces N2O emissions and improves nitrogen uptake and use efficiency by crops by reducing soil compaction

Improved field access and extended possible operation time: CTF improves field access and extends possible operation time for spraying operations, for example

Reduced energy demand and increased productivity: CTF significantly reduces energy demand for all soil operations, especially tillage operations, by reducing soil compaction, by up to 50%

Improved precision and control of operation: Designed for tractors up to high horsepower, HLM’s C02-6810-180W Electric Transaxle further improves efficiency and simplifies maintenance through a new concept, making vehicle operation more efficient and resource-saving. This continuously variable transmission ratio enables the tractor to start and stop on slopes without using the clutch or brakes, virtually eliminating operating errors.

Supports sustainable agricultural practices: By keeping equipment in good condition, waste is reduced and long-term productivity is promoted. Reliable parts and service allow farmers to focus on their work, knowing that their machinery is up to the task.

Improved traction and reduced rolling resistance: Optimized wheel slip and reduced rolling resistance can reduce soil damage and lower fuel consumption.

Through these examples, we can see how the use of electric transaxles in agricultural machinery can improve efficiency, reduce costs, reduce environmental impact, and support sustainable agricultural practices.