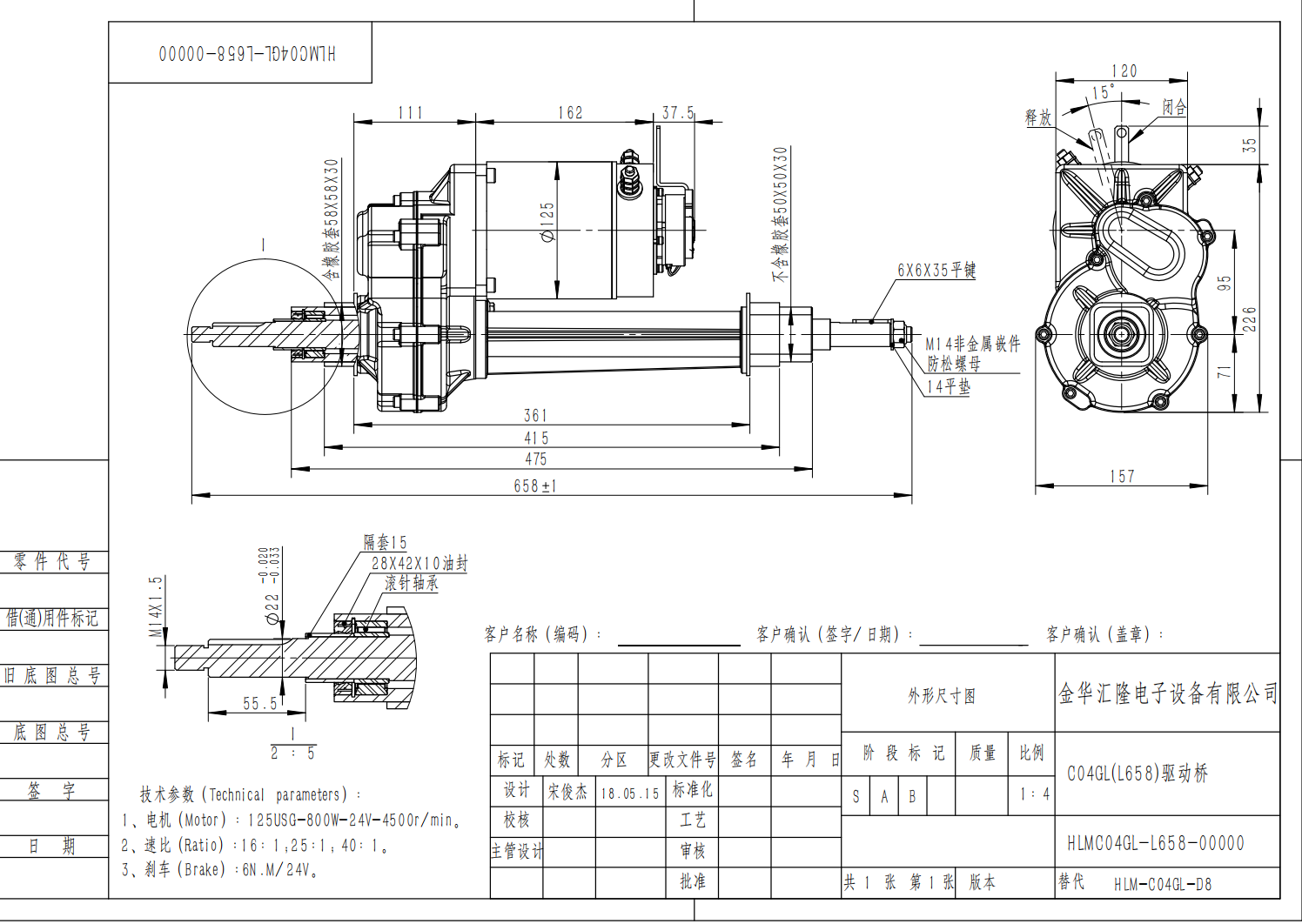

C04GL-125USG-800W Electric Transaxle For Heavy Duty Mobility Scooters

Key Features

Powerful and Efficient Motor

The heart of the C04GL-125USG-800W electric transaxle is its 125USG-800W-24V-4500r/min motor. This high-performance motor operates at 24V and has a high-speed rating of 4500 revolutions per minute (r/min), ensuring quick and efficient movement。 This speed not only allows for swift travel but also provides the torque necessary for climbing inclines and traversing rough terrains with ease.

Versatile Speed Ratios

The C04GL-125USG-800W electric transaxle is equipped with adjustable speed ratios, catering to various user preferences and terrain conditions:

16:1 Ratio: This ratio offers a balance of speed and torque, making it suitable for general use where a mix of both is required.

25:1 Ratio: For those who need a bit more torque for inclines or heavy loads, this ratio provides the necessary power without sacrificing too much speed.

40:1 Ratio: The highest ratio is ideal for applications where maximum torque is needed, such as moving through soft ground or steep hills.

These ratios allow the scooter to be tailored to the user’s specific needs, ensuring optimal performance in any situation.

What safety features does the 6N.M brake have?

The 6N.M brake, as detailed in the search results, offers several key safety features that enhance its performance and reliability in various applications, including heavy-duty mobility scooters. Here’s a breakdown of the safety features associated with a 6N.M brake:

High Braking Torque: The 6N.M brake is designed to provide a substantial braking torque of 6 Newton-meters (N.M), ensuring reliable stopping power even under heavy loads or in demanding conditions

Compatibility with Different Voltages: The brake is available in versions that operate at different voltages, such as 24V and 36V. This versatility allows for the brake to be used in a wide range of applications, ensuring compatibility with various mobility scooter systems

Spring-Applied, Electrically Released Mechanism: The 6N.M brake operates on a spring-applied, electrically released principle. This means that the brake is normally engaged due to a spring force and is released when electricity is applied, making it a fail-safe design. In the event of a power failure, the spring ensures that the brake is applied, preventing unintended movement

Low Noise Operation: The brake is designed to operate silently, with noise levels below 70 dBA, contributing to a safer and more comfortable operating environment

Durable Construction: The brake’s coil is covered and encircled by epoxy resin, and mechanical parts are protected by heat-resistant coating materials. This enhances the protection capacity of its inner structure and ensures durability under various conditions

Rapid Heat Radiation: The brake can be installed directly onto the motor end-cap, which serves as the brake surface. This design allows for rapid heat radiation, preventing overheating and maintaining the brake’s performance

Simplified Installation and Maintenance: The 6N.M brake is designed for easy installation and maintenance, reducing downtime and ensuring that the brake remains in optimal condition

Compatibility with All Materials: The brake fluid used in the system is compatible with all materials used in the brake system, preventing corrosion and ensuring smooth operation

High Boiling Point: The brake fluid has a high boiling point, which prevents vapor lock and ensures consistent performance even under high temperatures

Optimal Lubrication: The brake system components are protected by optimal lubricants, reducing abrasion and extending the life of the brake

These safety features make the 6N.M brake a reliable choice for heavy-duty mobility scooters, providing the necessary stopping power, durability, and safety required for such applications.