C05L-AC2.2KW Electric transaxle For AGV Equipment

Product Details

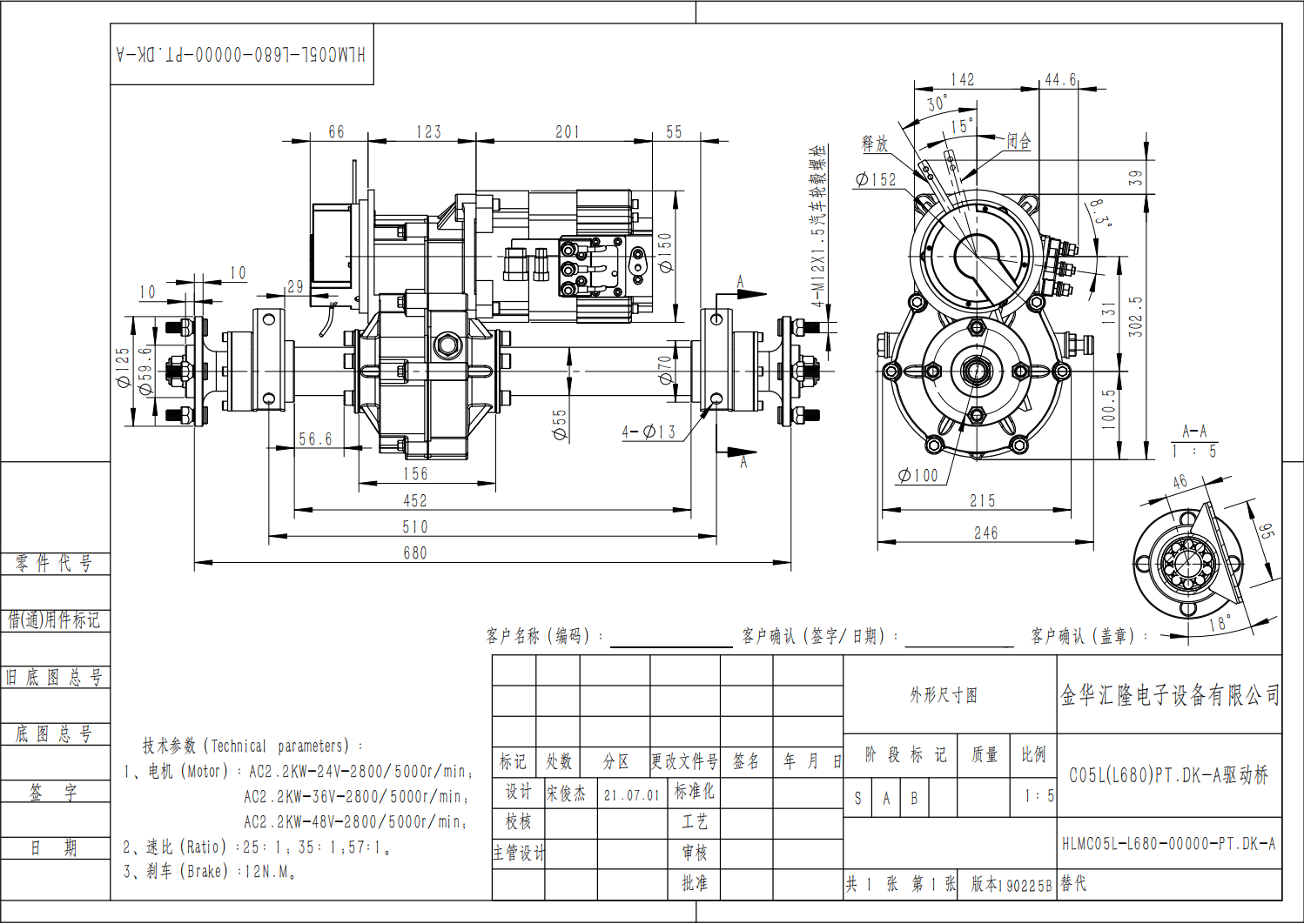

1. Motor: AC2.2KW-24V-2800/5000r/min;

AC2.2KW-36V-2800/5000r/min;

AC2.2KW-48V-2800/5000r/min;

2. Speed ratio: 25:1; 35:1; 57:1.

3. Brake: 12N.M

Product Advantages Performance

Powerful power, improved handling efficiency

High-efficiency motor: The AC2.2KW motor equipped with the C05L-AC2.2KW Electric transaxle has three voltage specifications of 24V, 36V, and 48V, which can be flexibly adapted to the power supply system of the AGV equipment. The rated power of the motor is up to 2.2KW, and it can output strong and stable power within the speed range of 2800r/min to 5000r/min. When the AGV equipment is carrying heavy objects, the motor can provide sufficient traction, allowing the AGV vehicle to easily drag the goods, quickly complete the handling task, and significantly improve the handling efficiency. For example, in large warehouses, AGV equipment needs to move tons of goods. The motor of C05L-AC2.2KW Electric transaxle can ensure that the AGV equipment still maintains a stable driving speed when fully loaded, avoiding delays in transportation due to insufficient power.

Precise speed ratio adjustment: The electric transmission device provides three speed ratio options: 25:1, 35:1, and 57:1. Different speed ratios can be precisely adjusted according to the driving needs and working scenarios of the AGV equipment. In scenarios where fast transportation is required, a lower speed ratio can be selected to enable the AGV equipment to achieve a higher driving speed and shorten the transportation time; in scenarios where greater traction is required, a higher speed ratio can be selected to enable the AGV equipment to easily overcome resistance and drag heavier goods. This precise speed ratio adjustment function enables AGV equipment to perform at its best under various working conditions

Stable driving and enhanced operating safety

Smooth starting and acceleration: Thanks to the motor’s high efficiency and precise speed ratio adjustment, the C05L-AC2.2KW Electric transaxle can make AGV equipment more stable during the starting and acceleration stages. When the AGV equipment starts, the motor can respond quickly and provide a smooth acceleration process to avoid cargo dumping or equipment damage caused by too aggressive starting. For example, in narrow warehouse aisles, AGV equipment needs to start and stop frequently. The C05L-AC2.2KW Electric transaxle can ensure that the AGV equipment is stable and smooth every time it starts, reducing safety hazards caused by unstable starting

Precise control of driving direction: The electric transmission device works closely with the navigation system of the AGV equipment to accurately control the driving direction of the AGV equipment. During the driving process of the automatic guided vehicle, the electric transmission device can accurately adjust the driving speed and direction according to the instructions of the navigation system, so that the AGV equipment can drive stably along the predetermined path. Even in complex road conditions or scenes requiring frequent turns, the AGV equipment can maintain a stable driving posture to avoid collision accidents caused by driving deviations

Reliable braking to ensure the safety of equipment and cargo

Powerful braking system: C05L-AC2.2KW Electric transaxle is equipped with a powerful 12N.M braking system. When the AGV equipment needs to slow down or stop, the braking system can respond quickly and provide strong braking force. For example, when the AGV equipment needs to stop after carrying goods to the designated location, the braking system can make the AGV equipment slow down smoothly to stop in a short time, avoiding cargo collision or equipment damage caused by untimely braking. At the same time, in emergency situations, such as obstacles or pedestrians suddenly appearing in front, the braking system can also ensure that the AGV equipment stops in time to ensure the safety of equipment and personnel

Reliable braking performance: The braking system adopts advanced braking technology and materials, with good reliability and durability. During long-term, high-intensity use, the brake system can maintain stable braking performance and will not fail due to wear or overheating. This provides a strong guarantee for the long-term stable operation of AGV equipment

A German company’s actual case description

A German company that mainly sells AGV equipment decided to upgrade its AGV equipment in the face of fierce market competition and customers’ increasing requirements for equipment performance. They chose C05L-AC2.2KW Electric transaxle as the core transmission device of AGV equipment. After the upgrade, the performance of the company’s AGV equipment has been significantly improved

Performance improvement

The handling efficiency has been significantly improved: After upgrading the C05L-AC2.2KW Electric transaxle, the handling efficiency of AGV equipment has increased by 40%. The strong power output and precise speed ratio adjustment of the motor enable AGV equipment to complete handling tasks faster. In the parts warehouse of a large automobile manufacturing plant in Germany, the upgraded AGV equipment can quickly move parts from the warehouse to the production line, greatly shortening the supply time of parts and ensuring the smooth operation of the production line

Enhanced driving stability: The upgraded AGV equipment is more stable during driving. Smooth starting and acceleration, as well as precise driving direction control, enable AGV equipment to operate safely and efficiently in complex factory environments. For example, in the assembly workshop of an automobile manufacturing plant, AGV equipment needs to shuttle through narrow passages and busy production areas. The upgraded equipment can maintain a stable driving posture, avoiding damage to parts or production delays caused by unstable driving

More reliable braking performance: The powerful braking system ensures that the AGV equipment can brake in time and smoothly when it needs to slow down or stop. In the warehouse of a German electronic component manufacturer, the upgraded AGV equipment can accurately stop at the designated location when carrying precision electronic components, avoiding component collision and damage caused by untimely braking, and ensuring the safety of the goods.

Improved efficiency and sales

Improved equipment operation efficiency: As the performance of AGV equipment has been comprehensively improved, the operating efficiency of the equipment has also been significantly improved. Among the customers of German companies, a logistics company has increased the cargo turnover rate of its warehouse by 30% after using the upgraded AGV equipment. AGV equipment can complete the handling and sorting of goods faster, reduce the time that goods stay in the warehouse, and improve the efficiency of the entire logistics system.

Significant sales growth: The performance improvement makes the AGV equipment of German companies more competitive in the market. Customer satisfaction with the upgraded equipment has greatly increased, and word of mouth has spread. Within a year, the company’s AGV equipment sales increased by 50%. In order to improve their own logistics efficiency and automation level, many companies have purchased the company’s AGV equipment, which has continuously expanded the company’s market share.