How are drive axles used in material handling systems?

As a core component in material handling systems, drive axles are widely used and crucial. Here are some examples of drive axles used in material handling systems:

1. Improve efficiency and carrying capacity

The drive axle can bear the weight of the material handling vehicle and provide enough power to move the heavy load. For example, the special-shaped drive axles provided by NAF AG have a payload range of 10-50 tons and are suitable for rugged terrain and harsh working conditions. They are widely used in forestry, agriculture, mining and material handling industries.

2. Precision control and efficient coordination

With the application of intelligent technology, drive axles integrate advanced sensors, control algorithms and communication technologies to achieve precision control and efficient coordination. This is especially important in material handling systems because it can improve the accuracy and efficiency of operations.

3. Lightweight design

The application of lightweight materials is an important direction for the development of drive axle technology. Using lightweight materials such as aluminum alloy and magnesium alloy to replace traditional materials can significantly reduce the weight of the drive axle, improve fuel economy and endurance, which is a significant advantage for material handling vehicles

4. Enhanced durability and reduced noise

In terms of noise reduction and enhanced durability, the R&D personnel of the drive axle continue to explore new sound insulation materials and structural designs, effectively reducing noise during operation and improving durability

5. Adapt to different road conditions

The drive axle distributes power to the left and right drive wheels through the differential, so that the left and right drive wheels have a reasonable speed difference, allowing the car to travel under different road conditions, which is particularly important for material handling vehicles in a changing working environment

6. Application of structural transport vehicle drive axles

In the field of material handling, the structural transport vehicle drive axle can realize the lifting and lowering of flatbed trucks, including a structural axle housing assembly and a leaf spring seat fixed horizontally at both ends of the structural axle housing assembly. This design improves the safety performance of the vehicle and optimizes the appearance structure of the leaf spring seat

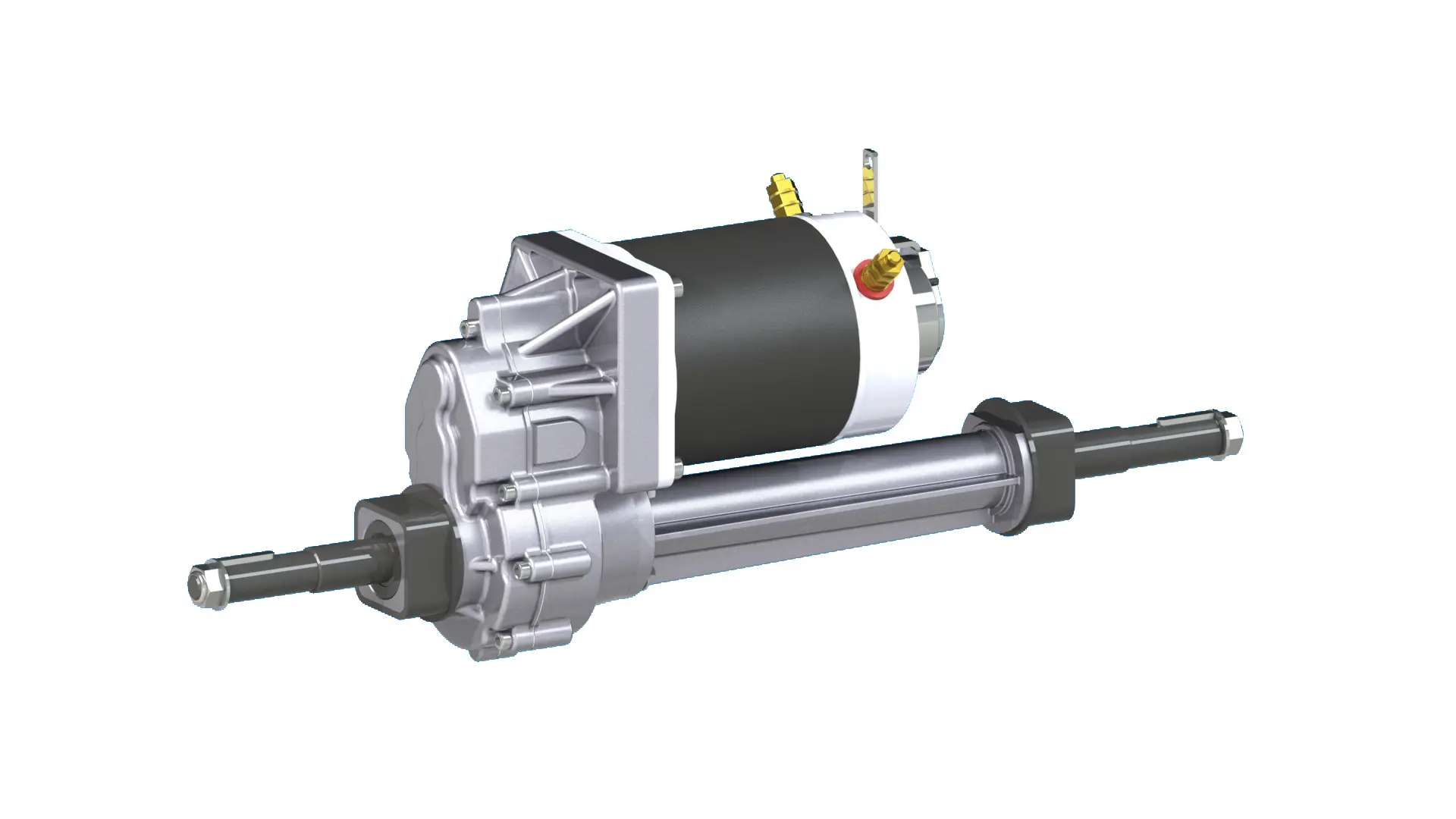

7. New energy commercial vehicle drive solution

The application examples of electric drive axles for new energy commercial vehicles show that while providing load-bearing, driving and braking functions, the drive axle converts the electrical energy in the battery into mechanical energy for driving. It has two major technologies: integrated wheel-side drive and regenerative braking. It eliminates components such as the transmission, clutch and drive shaft, reduces the number of vehicle parts and saves costs.

In summary, the application of drive axles in material handling systems is reflected in improving efficiency, load-bearing capacity, precise control, lightweight design, enhanced durability, adaptability to different road conditions and new energy drive solutions. With the continuous advancement of technology, the application of drive axles in material handling systems will be more extensive and efficient.

Post time: Dec-30-2024