How Does a 1.5KW Electric Transaxle Improve Safety in Material Handling?

Introduction

In the dynamic landscape of material handling, safety stands as the cornerstone of operational excellence. The integration of advanced technologies and equipment has become imperative to mitigate risks and enhance workplace safety. Among these innovations, the 1.5KW electric transaxle has emerged as a pivotal component, revolutionizing the way materials are transported and managed. This comprehensive blog post delves into the multifaceted role of the 1.5KW electric transaxle in improving safety within material handling operations, exploring its mechanisms, benefits, and real-world applications.

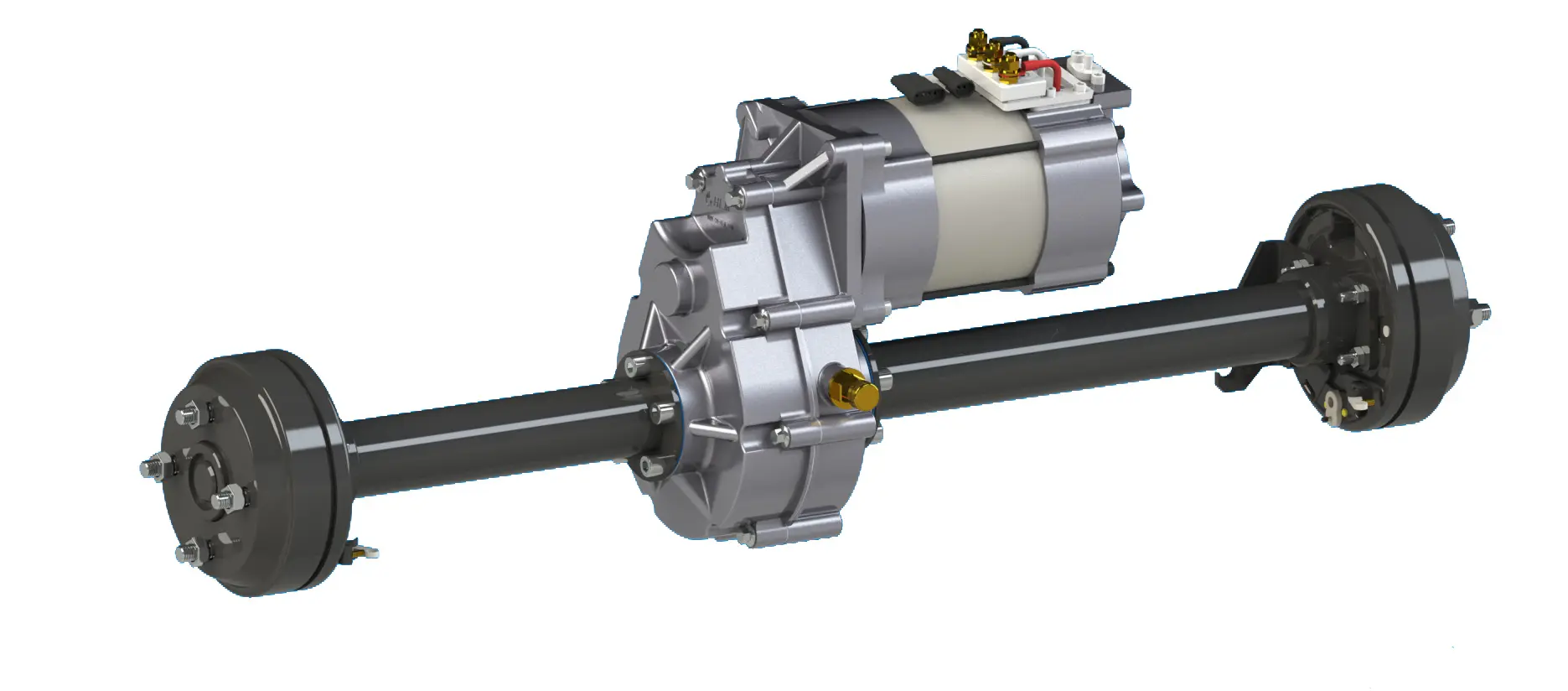

Understanding the 1.5KW Electric Transaxle

The 1.5KW electric transaxle represents a significant advancement in power transmission technology. Designed to deliver high torque and efficient power output, this compact yet powerful unit is engineered to meet the demands of modern material handling equipment. Its integration into various applications, such as automated guided vehicles (AGVs), conveyor systems, and other material transport mechanisms, underscores its versatility and reliability.

Mechanisms for Enhancing Safety

Precision Control and Stability

One of the primary contributions of the 1.5KW electric transaxle to material handling safety lies in its ability to provide precise control over movement and load management. The transaxle’s design allows for accurate speed regulation, ensuring that materials are transported at optimal velocities that prevent instability and potential accidents. This precision is particularly crucial when navigating tight spaces, uneven surfaces, or congested areas within warehouses and distribution centers.

Reduced Physical Strain on Operators

Manual material handling often exposes workers to risks of musculoskeletal disorders (MSDs) due to repetitive lifting, pushing, or pulling of heavy loads. The 1.5KW electric transaxle-powered equipment significantly reduces the physical strain on operators by automating these tasks. By transferring the workload to the machinery, the transaxle helps prevent injuries associated with overexertion, promoting a safer and more ergonomic working environment.

Enhanced Load Security

The transaxle’s robust construction and high torque output enable it to securely handle heavier loads without compromising stability. This feature is vital in preventing load shifts or drops, which can lead to accidents and damage to materials or equipment. The secure grip on loads ensures that materials remain in place throughout the handling process, minimizing the risk of collisions or spills.

Integration with Safety Systems

Modern 1.5KW electric transaxles are often equipped with advanced safety features such as electromagnetic intelligent brake systems. These systems provide superior braking capabilities, especially on slopes, preventing unintended movements and ensuring that equipment comes to a safe stop when required. Additionally, the transaxle can be integrated with sensors and monitoring systems to detect obstacles, monitor load conditions, and alert operators to potential hazards in real-time.

Applications in Material Handling

Automated Guided Vehicles (AGVs)

AGVs equipped with 1.5KW electric transaxles have transformed the landscape of warehouse automation. These autonomous vehicles follow predefined paths, reducing the risk of human error and collisions. The transaxle’s reliability and efficiency enable AGVs to operate continuously with minimal downtime, enhancing overall productivity while maintaining a high standard of safety.

Conveyor Systems

In conveyor-based material handling, the 1.5KW electric transaxle ensures smooth and consistent movement of materials along the conveyor belts. Its ability to handle varying loads and maintain steady operation prevents jamming and overflow, which can lead to hazardous situations. The transaxle’s integration with conveyor systems also allows for synchronized movement, reducing the likelihood of misalignment and associated safety risks.

Mobile Robots and Collaborative Robots (Cobots)

The deployment of mobile robots and cobots in material handling environments has increased efficiency and safety. The 1.5KW electric transaxle powers these robots, enabling them to navigate complex environments, lift and transport materials, and interact safely with human workers. The transaxle’s compact size and high power density make it ideal for integration into these agile and versatile robotic systems.

Case Studies and Real-World Impact

Manufacturing Facilities

In manufacturing settings, the implementation of 1.5KW electric transaxle-driven material handling systems has led to a notable reduction in workplace injuries. For instance, a case study from a manufacturing plant demonstrated a 30% decrease in injury rates after introducing ergonomic training and automated material handling equipment powered by efficient transaxles.

Warehousing and Distribution Centers

Warehouses and distribution centers have experienced enhanced safety and operational efficiency through the use of AGVs and conveyor systems equipped with 1.5KW electric transaxles. These systems have minimized the need for manual handling, reducing the risk of accidents related to forklift operations and improper load management.

Future Trends and Innovations

Smart Transaxles and IoT Integration

The future of material handling safety is intertwined with the evolution of smart technologies. Smart transaxles, equipped with IoT capabilities, can collect and analyze data related to performance, load conditions, and environmental factors. This data-driven approach enables predictive maintenance, real-time risk assessment, and proactive safety measures, further enhancing the safety profile of material handling operations.

Advanced Sensor Technology

Integration with advanced sensor technology, such as LiDAR and computer vision, allows the 1.5KW electric transaxle to operate in increasingly complex and dynamic environments. These sensors enable the equipment to detect and respond to obstacles, personnel, and changing conditions with heightened accuracy, reducing the risk of accidents and improving overall safety.

Conclusion

The 1.5KW electric transaxle stands as a beacon of innovation in the realm of material handling safety. Its ability to provide precise control, reduce physical strain, enhance load security, and integrate with advanced safety systems makes it an indispensable component in modern material handling operations. As industries continue to evolve and adopt smarter technologies, the role of the 1.5KW electric transaxle in ensuring a safe and efficient working environment will only become more pronounced. By embracing these technological advancements, businesses can not only improve safety outcomes but also drive productivity and competitiveness in the global marketplace.

Post time: Mar-26-2025