How to choose a high-quality drive axle for a cleaning vehicle?

The drive axle of a cleaning vehicle is one of the key components to ensure the efficient operation of the cleaning vehicle. When purchasing a high-quality drive axle for a cleaning vehicle, multiple factors need to be considered to ensure its performance, durability and reliability. Here are some important purchasing guidelines:

1. Understand the basic functions and types of drive axles

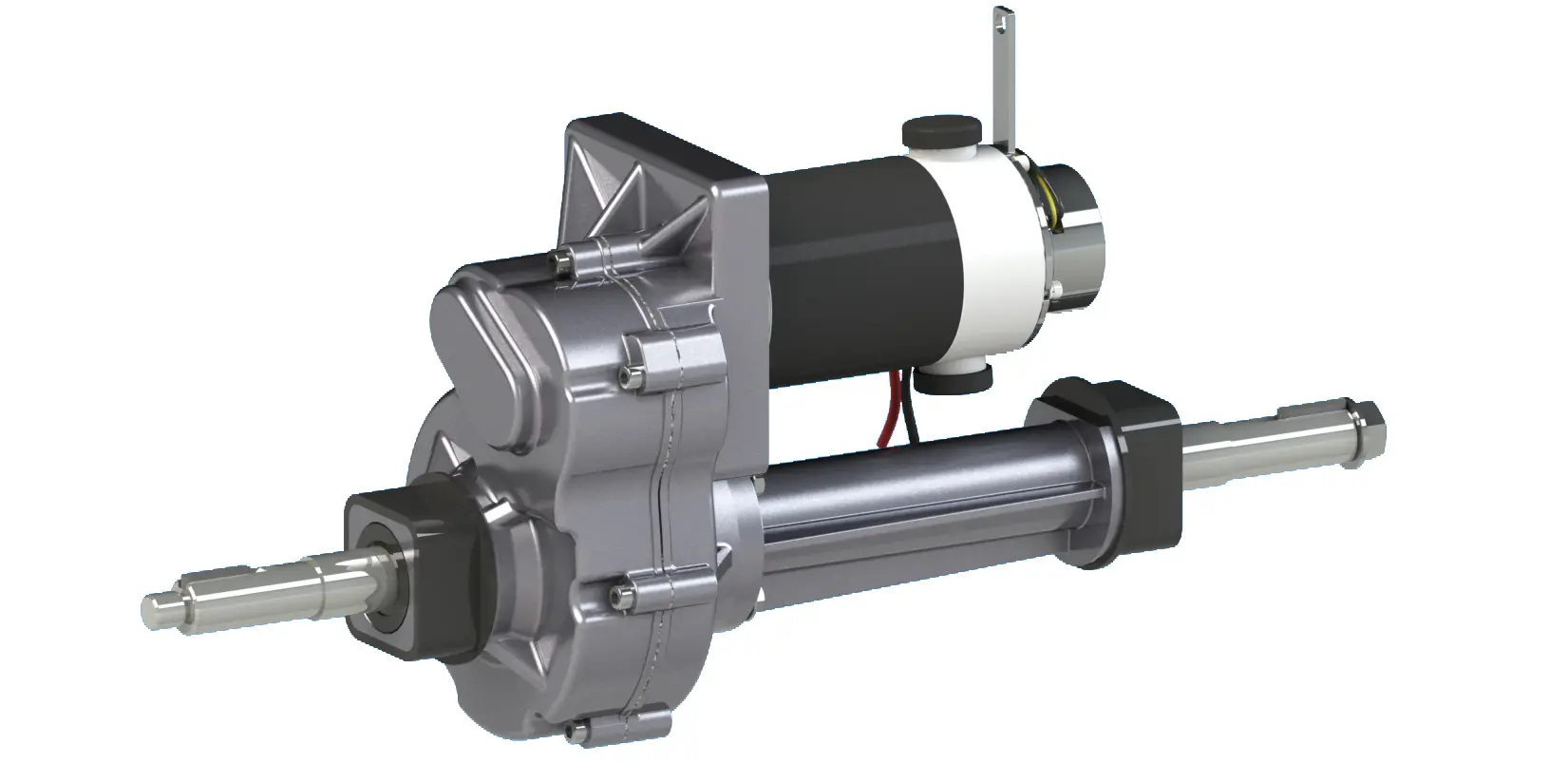

The main functions of drive axles include deceleration, torque increase, change of torque transmission direction, differential, load bearing and force transmission. Understanding these functions will help you choose a drive axle that suits your specific cleaning vehicle needs. The types of drive axles include integral and disconnected types, each with its specific application scenarios and advantages and disadvantages

2. Choose a well-known brand

Choosing a drive axle from a well-known brand can ensure product quality and after-sales service

3. Check the cleanliness standard

Cleanliness is one of the important indicators of drive axle performance. According to the DB34/T 1737-2012 standard, understand the limits and evaluation methods of the cleanliness of the drive axle assembly, which includes term definitions, sampling, inspection items and requirements, limits and measurement methods. Choosing a drive axle that meets this standard can ensure its internal cleanliness and reduce the risk of wear and failure.

4. Consider materials and manufacturing processes

High-quality materials and advanced manufacturing processes are key to the durability and reliability of drive axles. Drive axles made of high-strength steel and other wear-resistant materials should be selected, and precision machining technology should be used to ensure the precise fit of components

5. Evaluate performance parameters

Performance parameters such as the main reduction ratio, bevel gear meshing footprint, gear bending fatigue strength, etc. are important indicators for evaluating the performance of drive axles. Selecting a drive axle with performance parameters that meet or exceed industry standards can ensure that it can operate stably under various working conditions.

6. Consider maintenance costs

Low maintenance costs are key to reducing operating costs. Choosing a drive axle that is easy to maintain and repair can reduce downtime caused by repairs and reduce long-term operating costs. At the same time, consider the warranty policy and after-sales service network of the drive axle, and choose a brand that provides good after-sales support

7. Compare price and performance

Within the budget, compare the price and performance of drive axles of different brands and models, and choose the product with the best cost performance. Price does not always represent quality, so factors such as performance, durability and brand reputation should be considered comprehensively

8. Consider environmental performance

As environmental awareness increases, it is becoming increasingly important to choose a drive axle with good environmental performance. For example, choosing a drive axle with a lightweight design can reduce energy consumption and emissions

Conclusion

Purchasing a high-quality drive axle for a cleaning vehicle requires comprehensive consideration of multiple factors, including brand, performance parameters, cleanliness standards, materials and manufacturing processes, maintenance costs, and environmental performance. By carefully evaluating these factors, you can ensure that the drive axle you choose can meet the needs of the cleaning vehicle and provide efficient and reliable power transmission, thereby improving the working efficiency and economic benefits of the cleaning vehicle.

Post time: Dec-27-2024