How to ensure the quality of maintenance of electric transaxle of cleaning vehicle?

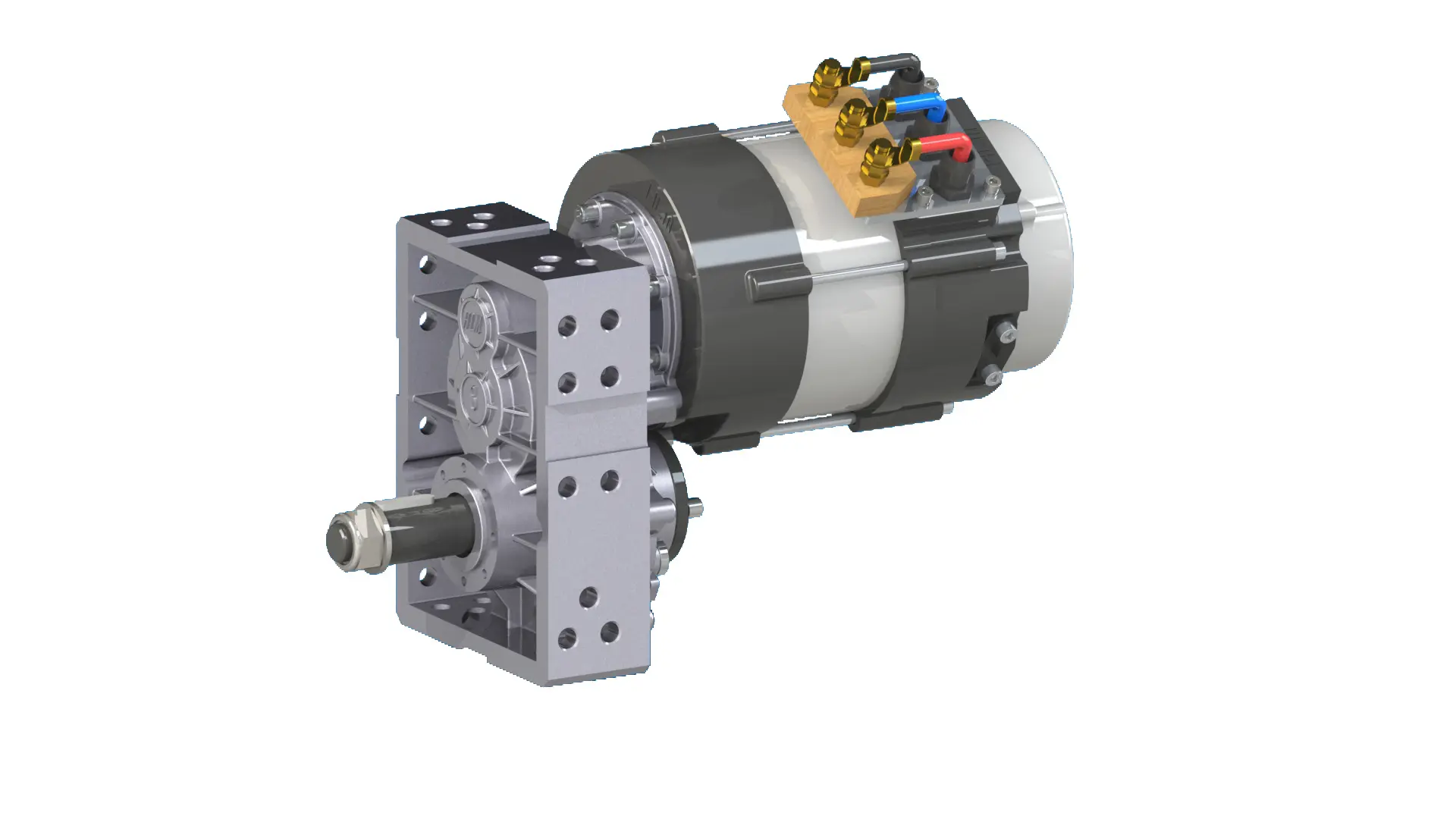

As the core power transmission system of cleaning vehicle, electric transaxle plays a vital role in the performance, efficiency and life of the vehicle. In order to ensure the quality of its maintenance, so as to ensure the normal operation of cleaning vehicle and extend its service life, the following will be elaborated in detail from multiple aspects.

1. Basic maintenance points of electric transaxle of cleaning vehicle

(i) Regular inspection of motor brushes

Motor brushes are one of the key components affecting the performance of electric transaxle. About 70% of motor failures are related to worn brushes. Therefore, it is necessary to check the wear of brushes every six months. If the brushes are severely worn, it will cause unstable operation of the motor or even damage, which will affect the normal operation of the entire transaxle. Regular inspection can timely detect brush problems, replace them in advance, and avoid potential expensive repair costs.

(ii) Lubrication

Lubrication is essential for the performance of electric transaxle. It is recommended to use synthetic oil for lubrication every 200 working hours to reduce friction and improve efficiency. Good lubrication can extend the service life of transaxle and keep it in good performance for more than 3000 working hours. During the lubrication process, make sure to use the appropriate lubricant and follow the correct lubrication method to avoid component damage caused by improper lubrication.

(III) Temperature range control

Extreme temperatures can have an adverse effect on the internal components of the electric transaxle. Therefore, it is recommended to operate these devices within a safe temperature range of -20°C to 40°C to prevent startup and performance problems. In high temperature environments, the viscosity of the oil will decrease, which may lead to insufficient lubrication and increased component wear; while in low temperature environments, seals may become brittle and easily break, causing oil leakage and other problems. Therefore, try to avoid using the cleaning car in an environment outside the recommended temperature range, or take appropriate temperature adjustment measures.

(IV) Tighten the connection

Loose connections can cause power loss and affect equipment performance. Check and tighten the connections regularly to maintain a stable current flow and prevent performance degradation. During the use of the cleaning car, the connection parts may become loose due to vibration and other factors. Therefore, all electrical connections, mechanical connections, etc. should be checked and tightened regularly to ensure that the connections between the components are firm and reliable.

(V) Debris Management

The impact of debris on electric transaxles cannot be ignored. Nearly 40% of transaxle problems are caused by dust and debris. Keeping the equipment clean, using compressed air to blow out dust, and ensuring a clean working environment can extend the service life of the equipment. When cleaning, be careful to avoid water and detergent from entering the interior of the transaxle to avoid short circuits or other damage. At the same time, during the cleaning process, carefully check whether there is debris accumulation or blockage in each component, and clean it in time.

(VI) Battery Maintenance

Improper battery maintenance is the cause of 25% of transaxle failures. Make sure the battery is fully charged before use and store it properly. Checking the voltage level weekly and keeping the battery charge between 20% and 80% can significantly extend the battery life. The battery is an important power source for cleaning vehicles, and its condition directly affects the working efficiency and stability of the transaxle. Therefore, it is necessary to maintain the battery according to the correct charging method and storage conditions to avoid overcharging, over-discharging, and long-term idleness.

(VII) Load Management

Overloading can cause heat accumulation and motor failure. The load capacity specified by the manufacturer should be strictly followed to prevent unnecessary stress on components, thereby saving costs and optimizing performance. During the use of the cleaning vehicle, the workload should be reasonably arranged according to its designed load-bearing capacity to avoid problems such as overheating of the transaxle and motor damage due to overloading. At the same time, attention should also be paid to the vehicle’s driving speed and working intensity to avoid long-term high-intensity operation.

(VIII) Electrical system maintenance

Regular inspection of the electrical system is essential for equipment such as electric golf carts. Check all wires for signs of wear or damage, ensure that there are no rust or loose connections, and ensure that the battery charger is working properly. For cleaning vehicles, the normal operation of the electrical system is the basis for ensuring the normal operation of the transaxle. Electrical components such as wires, connectors, batteries, and motor controllers should be inspected and maintained regularly to detect and repair potential problems in a timely manner and ensure the stability and reliability of the electrical system.

II. Environmental adaptability maintenance recommendations for cleaning vehicle electric transaxle

(I) Maintenance in high temperature environment

In high temperature environments, the oil temperature of the electric transaxle will increase, which may cause the viscosity of the oil to decrease and the lubrication effect to deteriorate, thereby accelerating the wear of components. To deal with this situation, the following measures can be taken: Use high-temperature resistant lubricants and sealing materials to ensure good lubrication and sealing performance under high temperature conditions; Add heat dissipation devices, such as installing additional radiators or fans, to help reduce the temperature of the transaxle; Regularly check the oil temperature monitoring system to ensure that it is working properly so that temperature abnormalities can be detected in time and corresponding measures can be taken.

(ii) Maintenance in low temperature environment

The low temperature environment will make the seals fragile and easy to break, resulting in problems such as oil leakage. At the same time, the viscosity of the oil will also increase, affecting its fluidity, thereby reducing the lubrication effect. For low temperature environments, the following maintenance measures can be taken: Use lubricants and sealing materials suitable for low temperature environments, which can still maintain good performance at low temperatures; Preheat the transaxle before starting the equipment to reduce the viscosity of the oil and improve its fluidity; Regularly check the heating device and insulation measures to ensure its normal operation and prevent components from being damaged by low temperatures.

(iii) Maintenance in humid environments

In humid environments, electric transaxles are easily eroded by moisture, causing rust, corrosion and other problems, which in turn affect their performance and life. In order to cope with the humid environment, the following measures can be taken: use lubricating oil and sealing materials with moisture-proof and anti-corrosion properties to prevent moisture intrusion; install protective devices such as waterproof covers or sealing covers to protect the transaxle from rain and other moisture; regularly check the drain holes and vents to ensure that they are unobstructed so that the internal moisture and humidity can be discharged in time; strengthen the moisture-proof treatment of electrical components, such as using moisture-proof agents, sealants, etc., to prevent electrical short circuits and other faults.

III. Maintenance quality control of electric transaxle for cleaning vehicles

(I) Formulate a maintenance plan

In order to ensure the maintenance quality of electric transaxle for cleaning vehicles, it is essential to formulate a detailed maintenance plan. The maintenance plan should include regular inspections, maintenance, repairs and other contents, and clarify the time intervals, specific steps and responsible persons for each task. For example, monthly, quarterly, and annual maintenance plans can be formulated according to the operating time or use cycle of the equipment, and arrangements can be made for different maintenance items. At the same time, the maintenance plan should be adjusted and optimized in a timely manner according to the actual use of the equipment and the manufacturer’s recommendations to ensure its effectiveness and adaptability.

(II) Personnel training and qualification certification

The professional quality and skill level of maintenance personnel directly affect the quality of maintenance. Therefore, systematic training and qualification certification of maintenance personnel is a key link to ensure the quality of maintenance. The training content should cover the knowledge and skills of the structural principles, maintenance technology, fault diagnosis and troubleshooting of electric transaxle, so that maintenance personnel have a solid professional foundation and skilled operation ability. At the same time, maintenance personnel are encouraged to participate in relevant qualification certification examinations and obtain professional certification certificates to improve their professional quality and credibility. Regularly organize skill assessment and experience exchange activities to promote learning and improvement among maintenance personnel and continuously strengthen the overall strength of the maintenance team.

(III) Maintenance records and document management

Establishing a complete maintenance record and document management system is of great significance for tracking and analyzing the maintenance history of equipment, evaluating maintenance effects, and formulating future maintenance strategies. After each maintenance work is completed, the maintenance time, content, problems found, measures taken and other detailed information should be recorded in a timely and accurate manner, and archived. These records can not only serve as a reference for the operation status of the equipment, but also provide important historical data support when the equipment fails or requires major repairs. In addition, the technical data, maintenance manuals, parts drawings and other documents of the equipment should be properly kept and classified for maintenance personnel to check and use at any time.

IV. Maintenance of the cleaning function of the electric transaxle cleaning vehicle

(I) Maintenance of cleaning equipment

The cleaning function of the cleaning vehicle mainly depends on the various cleaning equipment it is equipped with, such as brushes, nozzles, vacuum cleaners, etc. The normal operation of these equipment is essential to ensure the cleaning effect. Therefore, the cleaning equipment should be inspected and maintained regularly to ensure that it is in good working condition. For example, check the wear of the brushes and replace the severely worn brushes in time to ensure the cleaning effect; clean the nozzles to prevent blockage and ensure uniform water spray; check the filter element and pipes of the vacuum cleaner to ensure that its suction is normal and can effectively collect dust and debris. At the same time, according to the instruction manual of the equipment, the cleaning equipment should be regularly maintained and debugged to extend its service life.

(II) Maintenance of the detergent system

The detergent system is an important part of the efficient cleaning of the cleaning vehicle. In order to ensure its maintenance quality, the detergent system needs to be maintained regularly. First, check the tightness of the detergent storage container to prevent the detergent from leaking or deteriorating; second, check whether the detergent delivery pipeline and nozzle are unobstructed to avoid blockage that affects the spraying effect of the detergent; third, regularly calibrate the detergent proportioning device to ensure that the ratio of detergent to water meets the requirements, so as to achieve a good cleaning effect without causing damage to the equipment or the environment. In addition, according to different cleaning tasks and objects, choose the appropriate detergent and operate it according to the correct method of use to avoid equipment damage or poor cleaning effect due to improper use of detergents.

(III) Maintenance of the garbage collection system

The garbage collection system is an important part of the cleaning vehicle, which is used to collect and store garbage and debris generated during the cleaning process. In order to ensure its normal operation and maintenance quality, the garbage collection system needs to be maintained regularly. First, check the sealing performance of the garbage bin to prevent the smell of garbage from leaking out or the garbage from scattering; second, clean the residual garbage and dirt inside the garbage bin to keep it clean and hygienic to avoid the breeding of bacteria and the impact on the subsequent garbage collection; third, check the mechanical parts of the garbage collection device, such as the lifting mechanism and dumping mechanism, to ensure that they are flexible and reliable and can smoothly complete the garbage collection and unloading operations. At the same time, according to the capacity and frequency of use of the garbage collection system, the garbage removal time should be reasonably arranged to avoid the garbage bin being overfilled and affecting the normal work of the cleaning vehicle.

V. Fault prevention and rapid response of electric transaxle for cleaning vehicles

(I) Fault prevention measures

In addition to the regular maintenance and care measures mentioned above, the reliability and stability of electric transaxle for cleaning vehicles can be further improved through the following fault prevention measures. First, install monitoring equipment, such as vibration sensors, temperature sensors, etc., to monitor the operating status of the transaxle in real time, detect abnormal conditions in time and issue alarms, so as to take measures in advance for maintenance and repair. Secondly, use advanced diagnostic technologies, such as fault diagnosis software and tools, to conduct regular comprehensive inspections and analyses of the equipment, detect potential fault hazards in advance, and formulate corresponding preventive measures. Furthermore, optimize the operating parameters of the equipment, and reasonably adjust the operating parameters of the electric transaxle, such as motor speed, torque output, etc., according to the actual working conditions and the manufacturer’s recommendations, to avoid the equipment being in a high load or unreasonable operating state for a long time, thereby reducing the probability of failure.

(II) Fault rapid response mechanism

Even if various preventive measures are taken, failures may still occur. Therefore, it is crucial to establish an efficient fault rapid response mechanism. When the equipment fails, maintenance personnel should be able to respond quickly and arrive at the site in time to troubleshoot and repair the fault. To this end, it is necessary to formulate a detailed emergency plan for failures, clarify the handling process, division of responsibilities and required resources when a failure occurs. At the same time, establish a spare parts inventory management system to ensure that common vulnerable spare parts and key components can be supplied in a timely manner, and reduce equipment downtime caused by waiting for spare parts. In addition, strengthen cooperation with equipment manufacturers or professional technical service teams, and when encountering complex or difficult to solve failures, timely obtain technical support and guidance to ensure that the failure is solved quickly and effectively.

(III) Case analysis and experience summary

By conducting in-depth analysis and summary of actual failure cases, we can continuously accumulate maintenance experience and improve the ability to prevent and handle failures. For example, the electric transaxle of a cleaning fleet frequently leaked oil. After investigation, it was found that the use of incompatible oil caused premature aging of the seal. By replacing it with high-quality, temperature-resistant oil and increasing the inspection frequency, the occurrence of oil leakage failures was significantly reduced and the service life of the transaxle was extended. Such case analysis can not only help maintenance personnel better understand the causes and solutions of failures, but also provide a reference for formulating more scientific and reasonable maintenance strategies. Therefore, it is necessary to regularly organize maintenance personnel to conduct case analysis and experience exchange activities, share successful experiences and lessons, and continuously improve the professional level and fault response capabilities of the entire maintenance team.

6. Future trends in the maintenance of electric transaxle cleaning vehicles

With the continuous advancement of science and technology and the development of the industry, the maintenance of electric transaxle cleaning vehicles will also present some new trends and characteristics. First, intelligent and automated maintenance technologies will be more and more widely used. For example, the use of Internet of Things technology to achieve remote monitoring and diagnosis of equipment, analysis and prediction of equipment operation data through intelligent algorithms, and advance arrangement of maintenance tasks to improve maintenance efficiency and accuracy. Secondly, the concept of green environmental protection and sustainable development will have a profound impact on maintenance work. In the maintenance process, more attention is paid to the use of environmentally friendly lubricants, detergents and other materials to reduce pollution to the environment; at the same time, by optimizing maintenance processes and resource utilization, energy consumption and waste generation in the maintenance process can be reduced. Furthermore, outsourcing and specialization of maintenance services will become a trend. With the intensification of market competition and the improvement of enterprises’ requirements for cost control, more and more enterprises may choose to outsource the maintenance of electric transaxle cleaning vehicles to professional maintenance service companies, and use their professional technical teams and advanced maintenance equipment to improve maintenance quality and efficiency, while reducing their own operating costs and management burdens.

In summary, ensuring the quality of electric transaxle cleaning vehicle maintenance requires starting from multiple aspects, including strict implementation of basic maintenance points, targeted measures for environmental adaptability maintenance, comprehensive guarantee of maintenance quality control, meticulous maintenance of cleaning functions, effective implementation of fault prevention and rapid response, and accurate grasp and active response to future trends. Through the implementation of these comprehensive measures, the performance, reliability and service life of electric transaxle cleaning vehicles can be effectively improved, providing solid technical support for the efficient operation of cleaning vehicles and the sustainable development of enterprises.

Post time: Mar-10-2025