Introduction

In the fast-paced world of material handling and logistics, efficiency, safety, and reliability are paramount. The equipment used in warehouses, manufacturing facilities, and distribution centers must meet high standards to keep operations running smoothly. One component that has gained significant attention for its ability to enhance the performance of material handling vehicles is the 1.5KW electric transaxle. This comprehensive guide will delve into the intricacies of the 1.5KW electric transaxle, its applications, benefits, and how it compares to other solutions in the market.

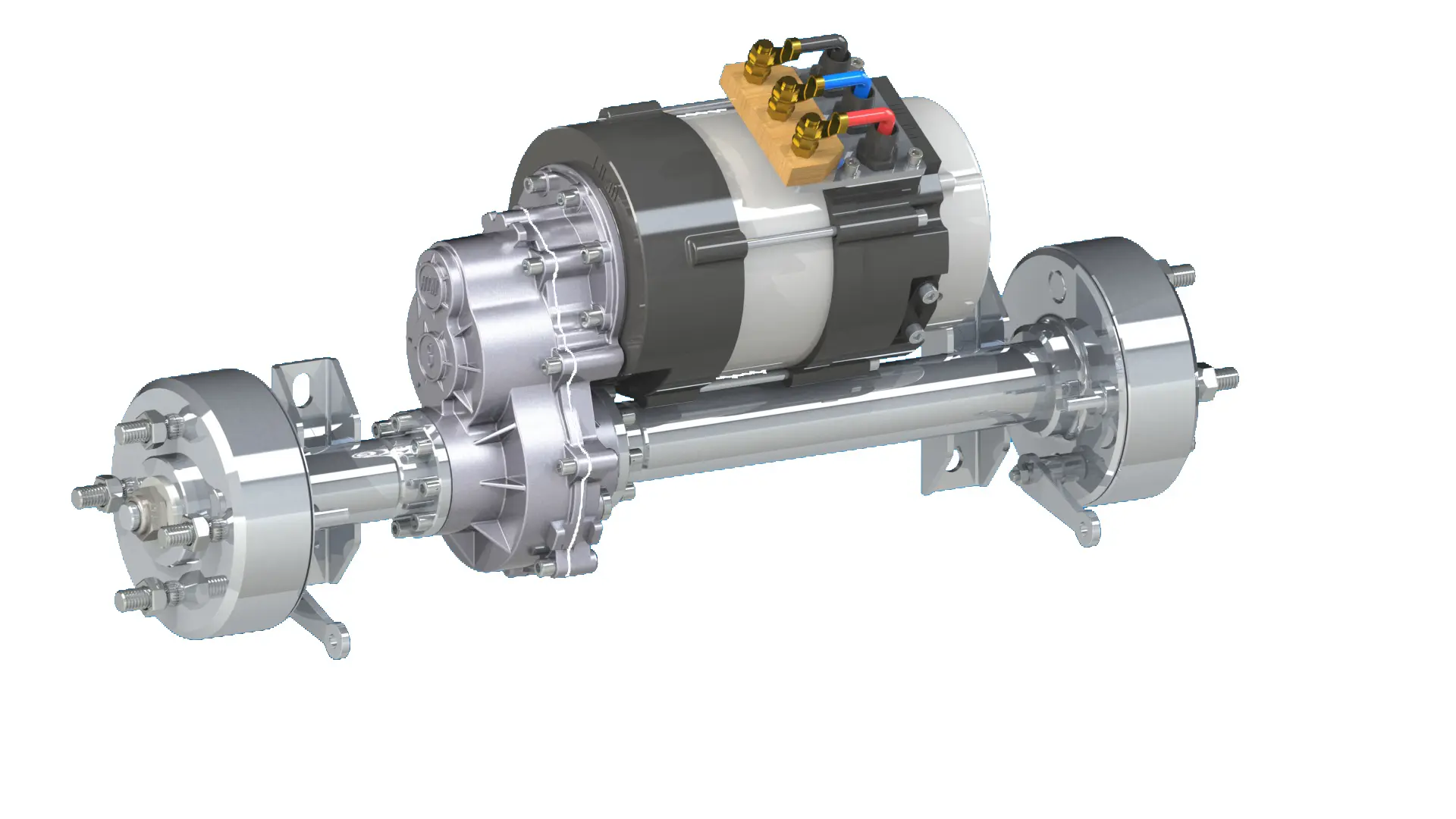

What is a 1.5KW Electric Transaxle?

A 1.5KW electric transaxle is a specialized powertrain component designed to deliver robust performance in material handling applications. It integrates an electric motor, gearbox, and braking system into a single unit, optimizing space and efficiency. The “1.5KW” designation refers to the power output of the electric motor, which is a key factor in determining the transaxle’s capability to handle various loads and tasks.

Core Components and Their Functions

Electric Motor: The heart of the transaxle, the electric motor converts electrical energy into mechanical power. In the case of the 1.5KW model, it provides a substantial 1.5 kilowatts of power, operating within a speed range that allows for precise control and adaptability to different material handling tasks.

Gearbox: The gearbox works in tandem with the motor to adjust the speed and torque output. It features specific gear ratios that can be customized to suit the requirements of different applications, whether that’s higher speed for quick movements or increased torque for heavy-duty tasks.

Braking System: Integrated braking mechanisms ensure safety and control. A high-torque brake system can bring equipment to a complete stop quickly and safely, preventing accidents and damage.

Applications in Material Handling Equipment

The versatility of the 1.5KW electric transaxle makes it suitable for a wide range of material handling equipment. Let’s explore some of the primary applications:

Electric Vehicles and AGVs

Automatic Guided Vehicles (AGVs) are staples in modern warehouses and manufacturing environments. The 1.5KW electric transaxle powers these vehicles, providing the necessary propulsion for efficient movement of materials. Its compact design allows for easy integration into AGV designs, while the high power output ensures reliable operation even in demanding conditions.

Sweepers and Floor Maintenance Equipment

Maintaining clean and safe floors is crucial in industrial settings. Sweepers equipped with the 1.5KW electric transaxle benefit from precise control and efficient operation, allowing for thorough cleaning without compromising on performance or battery life.

Forklifts and Pallet Trucks

In the realm of material lifting and transportation, forklifts and pallet trucks are indispensable. The 1.5KW electric transaxle offers the power needed to move heavy loads efficiently. Its ability to handle different terrains and loads makes it a reliable choice for these applications.

Advantages Over Other 24V Transaxles

When compared to other 24V transaxles available in the market, the 1.5KW electric transaxle stands out in several key areas:

Higher Power Output

With a robust 1500W of power, the 1.5KW electric transaxle surpasses many competitors that offer only 800W or 1000W. This increased power output translates to more efficient and effective operation, especially in scenarios requiring higher torque and speed.

Higher RPM for Faster Movements

The rated speed of 3500 RPM allows the transaxle to achieve faster speeds than some other models. This is particularly beneficial in applications where quick acceleration or covering larger distances in a shorter amount of time is necessary.

Integrated Design for Efficiency and Ease of Installation

The integration of the motor, controller, and gearbox into a single unit not only improves efficiency by reducing energy loss but also simplifies installation and maintenance. This compact design is more adaptable to various vehicle configurations compared to traditional setups with separate components.

Energy Efficiency

The combination of higher power output and efficient design makes the 1.5KW electric transaxle an energy-efficient solution. It can perform tasks more effectively while consuming less power, a significant advantage for battery-powered vehicles where energy conservation is crucial.

Technical Specifications and Customization Options

Understanding the technical specifications of the 1.5KW electric transaxle is essential for determining its suitability for specific applications.

Motor Specifications

Model: ACY1.5KW-24V-2800-5000rpm

Power: 1.5KW

Voltage: 24V

Speed Range: 2800 to 5000 revolutions per minute (rpm)

Pulses: 32 pulses for smooth and consistent power delivery

Gearbox Ratios

The transaxle offers two versatile ratio options:

24:1 Ratio: Ideal for applications requiring higher speed and quick movement, such as in warehouse environments where fast loading and unloading are essential.

33:1 Ratio: Provides increased torque, making it suitable for heavy-duty tasks that involve lifting or moving large loads.

Braking System

Type: 16N.M/24V brake system

Function: Ensures quick and safe stopping, preventing accidents and damage.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are crucial for maximizing the lifespan and performance of the 1.5KW electric transaxle.

Installation Guidelines

Alignment: Ensure proper alignment of the transaxle with the vehicle’s frame and other components to prevent unnecessary stress and wear.

Electrical Connections: Follow manufacturer specifications for wiring and connections to avoid electrical issues.

Lubrication: Apply appropriate lubricants to moving parts during installation to reduce friction and wear.

Maintenance Schedule

Daily Checks: Inspect for any visible damage or loose components. Check battery levels and connections.

Weekly Maintenance: Clean the transaxle and surrounding areas. Test the braking system for proper function.

Monthly Servicing: Perform more thorough inspections, including checking gear alignment and motor performance. Replace any worn parts as needed.

Case Studies and Real-World Applications

Examining real-world applications can provide valuable insights into the practical benefits of the 1.5KW electric transaxle.

Warehouse Automation Success Story

A major logistics company implemented AGVs equipped with the 1.5KW electric transaxle in their warehouse operations. The result was a 30% increase in efficiency, with reduced operational costs and improved safety records. The transaxle’s ability to handle varied loads and terrains within the warehouse environment proved to be a game-changer.

Manufacturing Floor Maintenance

A manufacturing facility struggling with floor maintenance inefficiencies switched to sweepers powered by the 1.5KW electric transaxle. The improved performance and extended battery life allowed for more thorough cleaning cycles without downtime, leading to a cleaner and safer working environment.

Future Trends and Innovations

The landscape of material handling equipment is continually evolving, driven by advancements in technology and changing industry demands.

Integration with IoT and Smart Systems

Future transaxles may feature enhanced connectivity, allowing for real-time monitoring and adjustment of performance parameters through IoT integration. This could lead to predictive maintenance and further optimization of material handling processes.

Advancements in Battery Technology

As battery technology improves, electric transaxles like the 1.5KW model will benefit from longer operational times and faster charging capabilities. This will expand their applicability in scenarios where continuous operation is critical.

Conclusion

The 1.5KW electric transaxle represents a significant advancement in powertrain technology for material handling equipment. Its combination of high power output, efficient design, and versatile applications makes it a superior choice for businesses seeking to enhance their operational efficiency and safety. By understanding its technical specifications, proper installation, and maintenance requirements, as well as exploring real-world applications, businesses can make informed decisions about integrating this technology into their operations.

FAQs

Q: What is the primary advantage of the 1.5KW electric transaxle over lower-powered models?

A: The primary advantage lies in its higher power output, which allows for more efficient handling of heavier loads and faster movements, ultimately improving overall operational efficiency.

Q: Can the 1.5KW electric transaxle be customized for specific applications?

A: Yes, with adjustable gear ratios and integration capabilities, it can be tailored to meet the specific needs of various material handling tasks.

Q: How does the integrated design of the 1.5KW electric transaxle benefit users?

A: The integrated design reduces energy loss, simplifies installation, and makes maintenance more straightforward, all while being more compact and adaptable to different vehicle designs.

Post time: Mar-24-2025